Welcome to the TAM8 Service Manual, your comprehensive guide for installing, maintaining, and troubleshooting the TAM8 air handler. This manual ensures optimal performance and safety, referencing ACCA standards and manufacturer guidelines for reliable operation.

1.1 Overview of the TAM8 Air Handler

The TAM8 Air Handler is a versatile and efficient HVAC system designed for residential and commercial applications. It features a two-piece cabinet design, ensuring easy installation and maintenance. The unit incorporates advanced diagnostic tools, such as fault codes and an alert system, to simplify troubleshooting. With its robust construction and user-friendly interface, the TAM8 is built to provide reliable heating, ventilation, and air conditioning solutions. Its compatibility with various heating elements and outdoor units makes it a flexible choice for diverse setups. This overview highlights the key characteristics and operational features of the TAM8, preparing technicians for in-depth service procedures outlined in subsequent sections.

1;2 Importance of the Service Manual

The TAM8 Service Manual is essential for ensuring the air handler operates efficiently and safely. It provides detailed installation, maintenance, and troubleshooting guidelines, helping technicians avoid costly errors. By following the manual, service personnel can identify and resolve issues quickly, minimizing downtime. The manual also references ACCA standards and includes wiring diagrams, parts lists, and diagnostic tools. It serves as a critical resource for understanding fault codes and performing routine checks. Adhering to the manual’s instructions ensures compliance with safety protocols and warranty requirements, protecting both the equipment and service personnel. This makes the manual indispensable for anyone working with the TAM8 system.

Key Features and Design Overview

The TAM8 air handler features a unique two-piece cabinet design, enhancing accessibility for maintenance and service. It includes advanced diagnostic tools, improving fault detection and repair efficiency significantly.

2.1 Unique Cabinet Design and Components

The TAM8 air handler boasts a distinctive two-piece cabinet design, constructed for durability and ease of access. This configuration allows service personnel to efficiently access internal components without extensive disassembly; The cabinet is designed with built-in support channels, facilitating the removal and reinstallation of major assemblies, such as the blower motor. Additionally, the structure includes features like isolators and a bottom support system to minimize vibrations and ensure stable operation. This innovative design not only streamlines maintenance but also protects internal electrical components from potential damage during servicing. The cabinet’s modular approach enhances serviceability, making it a practical solution for both installation and long-term upkeep.

2.2 Service Diagnostic Features

The TAM8 air handler is equipped with advanced diagnostic tools designed to simplify troubleshooting and maintenance. The system includes a fault code table, accessible via the Alert Menu, which provides detailed information about active and historical issues. This feature allows service technicians to quickly identify and address problems, ensuring minimal downtime. Additionally, the unit’s user interface provides real-time alerts, enabling prompt resolution of operational issues. These diagnostic capabilities, combined with comprehensive documentation, empower technicians to efficiently diagnose and repair faults, ensuring optimal performance and extending the lifespan of the equipment. The TAM8’s diagnostic features are a cornerstone of its service-friendly design, making it a reliable choice for heating and ventilation systems.

Installation and Setup

The TAM8 installation requires compatibility checks, wiring diagram reviews, and adherence to ACCA standards and manufacturer guidelines to ensure safe and efficient setup.

3.1 Compatibility Checks and Allowable Combinations

Ensuring compatibility is crucial for the TAM8 air handler. Reference ACCA Manual D, S, and RS for allowable combinations with outdoor units and accessories. Compatibility checks involve verifying electrical, mechanical, and performance specifications to maintain system efficiency. Proper wiring connections, as outlined in the wiring diagrams, are essential to prevent operational issues. Field wiring must align with the unit’s design, particularly for components like the blower assembly. Consult the service manual and product data for specific guidelines to ensure all combinations meet manufacturer standards and safety protocols.

3.2 Wiring Diagrams and Connections

Wiring diagrams are essential for proper TAM8 air handler installation. Schematic and pictorial diagrams provide detailed connections for compatibility with outdoor units. Field wiring must be routed correctly, ensuring all components, like the blower assembly, are securely connected. Disconnect wiring before servicing, using built-in support channels for safe removal. Verify heating element operation by switching to Emergency Heat and raising the thermostat setpoint. Always follow manufacturer guidelines to prevent electrical issues and ensure system efficiency. Consult the service manual for specific wiring instructions and safety precautions to maintain optimal performance and compliance with standards. Proper connections are vital for reliable operation and troubleshooting.

Maintenance and Service Procedures

Regular maintenance ensures TAM8 air handler efficiency and longevity. Follow routine checks, diagnostic tools, and service guidelines to prevent issues and maintain optimal performance safely and effectively.

4.1 Routine Maintenance Checks

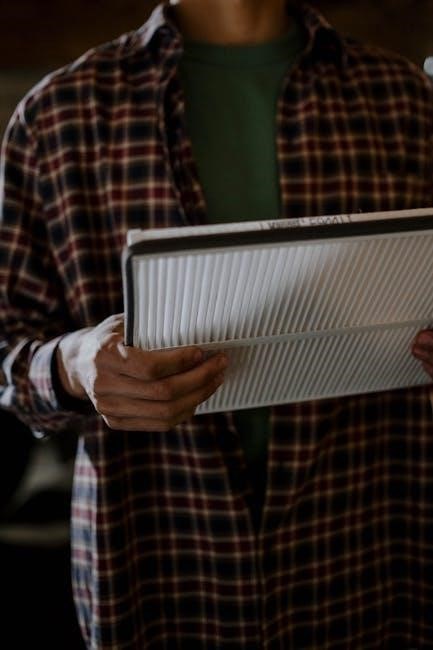

Performing routine maintenance checks on the TAM8 air handler is essential for ensuring efficient operation and preventing potential issues. Start by visually inspecting the unit for any signs of wear, damage, or debris buildup, especially around filters and coils. Check the air filter and replace it if dirty, as a clogged filter can reduce airflow and system performance. Next, examine the drain pan and ensure it is clear of blockages to prevent water damage. Inspect all electrical connections and wiring for any signs of fraying or corrosion. Ensure that all screws and fasteners are securely tightened to maintain proper alignment and function; Additionally, verify that the thermostat is calibrated correctly to ensure accurate temperature control. Schedule these checks at least twice a year, preferably before the start of heating and cooling seasons, to maintain optimal performance and extend the lifespan of the unit. Always refer to the service manual for specific guidance and safety precautions during these procedures.

4;2 Diagnostic Tools and Techniques

Diagnosing issues with the TAM8 air handler requires a combination of specialized tools and systematic techniques; Begin by reviewing the unit’s fault codes, which are listed in the Fault Table within the service manual. Use a multimeter to measure electrical resistance and voltage, ensuring all components are functioning within specified ranges. Inspect wiring connections and harnesses for damage or corrosion, referencing the wiring diagrams provided in the manual. Utilize the Alert Menu to access historical and active faults, which can provide insights into recurring issues. Additionally, perform visual inspections of components like coils, fans, and drains to identify blockages or wear. Always follow the diagnostic procedures outlined in the manual to ensure accurate troubleshooting and safe servicing of the unit.

Troubleshooting and Repair

Troubleshooting the TAM8 involves identifying symptoms, referencing fault codes, and performing repairs. Use diagnostic tools to isolate issues, ensuring efficient and accurate resolutions for optimal performance.

5.1 Common Issues and Solutions

Common issues with the TAM8 air handler include faulty wiring connections, malfunctioning heating elements, and blocked airflows. For wiring problems, consult the provided diagrams to ensure proper connections. Heating element issues may require replacing defective components. Airflow blockages can be resolved by cleaning filters or checking ductwork. Always refer to the fault table in the Service Facts for specific error codes and solutions. Addressing these issues promptly ensures efficient operation and prevents further damage. Regular maintenance, such as checking electrical connections and cleaning filters, can help minimize common problems and extend the unit’s lifespan.

5.2 Fault Codes and Their Meanings

The TAM8 air handler features a diagnostic system that displays fault codes to identify issues. Common codes include ‘E1’ for sensor malfunctions, ‘E2’ for communication errors, and ‘E3’ for overheating. These codes are accessible via the Alert Menu or the Service Facts section. Understanding these codes helps technicians pinpoint problems quickly. For example, ‘E1’ may indicate a faulty temperature sensor, while ‘E2’ could signal a loss of communication between components. Referencing the fault table in the Service Facts provides detailed explanations and solutions. Addressing these issues promptly ensures efficient operation and prevents further damage. Always consult the manual for specific troubleshooting steps tailored to each fault code.

Safety Precautions and Best Practices

Always disconnect power before servicing; Ensure proper electrical protection and follow safety protocols to prevent injuries and damage. Only qualified personnel should perform installations and repairs. Protect internal components during maintenance to ensure reliability and safety. Adhere to all guidelines to avoid hazards and guarantee optimal system performance. Consult the manual for detailed safety measures. Proper precautions prevent accidents and ensure compliance with industry standards. Regular safety checks are essential for long-term system reliability and user protection. Follow all manufacturer recommendations to maintain a safe working environment. Electrical safety is critical to prevent shocks or component damage. Always verify power disconnection before starting work. Use appropriate tools and wear protective gear. Ensure the system is grounded correctly to avoid electrical hazards. Never bypass safety features or ignore warning signs. Proper safety practices ensure efficient and risk-free service. Regular training on safety procedures is recommended for service personnel. Keep the area clean and well-ventilated during maintenance. Avoid overloading circuits or using damaged wiring. Follow local electrical codes and regulations. Ensure all connections are secure to prevent arcing or fires. Use lockout/tagout procedures to prevent accidental startups. Keep emergency contact information nearby. Familiarize yourself with emergency shutdown procedures. Never service the unit under hazardous conditions. Always refer to the manual for specific safety instructions. Safety is paramount to protect both personnel and equipment. Adherence to safety guidelines ensures a safe and efficient servicing experience. Proper safety practices are non-negotiable and must be strictly followed at all times.

6.1 General Safety Guidelines

Always disconnect power before servicing the TAM8 air handler to ensure safety. Use lockout/tagout procedures to prevent accidental startups. Only qualified personnel should perform maintenance or repairs. Wear appropriate protective gear, including gloves and safety glasses, when handling electrical or mechanical components. Ensure proper grounding of the system to avoid electrical hazards. Keep the work area clean and well-ventilated to prevent accidents. Never bypass safety features or ignore warning signs. Follow all local electrical codes and regulations during installation and servicing. Use approved tools and equipment to avoid damage to components. Regularly inspect wiring and connections for damage or wear. Ensure all electrical connections are secure to prevent arcing or fires. Familiarize yourself with emergency shutdown procedures before starting work. Keep emergency contact information nearby. Always refer to the manual for specific safety instructions. Adherence to these guidelines ensures a safe working environment and protects both personnel and equipment. Proper safety practices are essential for efficient and risk-free servicing. Regular safety checks and training are recommended to maintain compliance with industry standards.

6.2 Electrical Disconnect and Protection

Ensure an approved electrical disconnect is installed near the TAM8 air handler for safe servicing. This device must be easily accessible and lockable to prevent unintended power restoration. Use a disconnect that meets local electrical codes and is rated for the system’s voltage and current. Always verify the disconnect is in the off position before starting work. Test for voltage using a multimeter to confirm power is off. Never rely on the unit’s controls alone for electrical isolation. Install surge protectors or voltage regulators if necessary to safeguard against power spikes. Ensure all wiring connections are secure and properly insulated to prevent arcing or short circuits. Regularly inspect the disconnect and wiring for wear or damage. Replace any components showing signs of deterioration. Proper electrical protection enhances safety and extends equipment lifespan. Always follow manufacturer guidelines for disconnect installation and maintenance. This ensures compliance with safety standards and prevents potential hazards. Regular inspections and timely repairs are crucial for maintaining electrical integrity.